Modular

We derived our considerations from the automotive industry. The buzzword is “plug and play. ” What does this mean? We design and plan our modules so that they can be placed almost anywhere in the building and in this way the technical connections always work. Modular housing concepts offer solutions for almost all forms of living. Whether student housing or family accommodation, whether retirement homes or apartments for single people. In principle, modular concepts can be developed for almost all types of living. Maybe you are thinking about the construction kits that you played with as a child. Even back then, completely different designs could be implemented with a number of different modules. We take advantage of just this fact. If we deal with specific locations, we will use the existing modular system and create a perfect building solution for the respective location. In this way, people and their usage requirements are our main focus once again. Modular building concepts are quickly available in a number of ways. The construction time is significantly shortened, and the time required for the part of the building above ground amounts to a few weeks and when it comes to large building complexes, the construction period amounts to a few months. By making use of the existing planning modules, the planning time is significantly reduced. This significantly shortens the overall project duration. The capital commitment is shorter, less personnel costs, construction costs decrease, in short, the project becomes “affordable”. While the terrain is being prepared on the construction site or the basements are being built, the production of the building modules is underway at the manufacturing plant. As soon as the construction site has been approved for erecting the building, the modules are delivered. Reduce construction time and costs with modular concepts from Semodu

Keep it simple: : Industry as an example

This is also an aspect that in turn benefits shorter project lifetimes, improves quality and ultimately reduces construction costs. Our customers benefit from this by buildings with a short construction phase.

The potential of modular construction especially unfolds in the planning of entire residential districts or mixed-use properties. The economies of scale of modular design lead customers to be better profitability.

Clever Modules:

many possible applications

Quickly available and affordable too

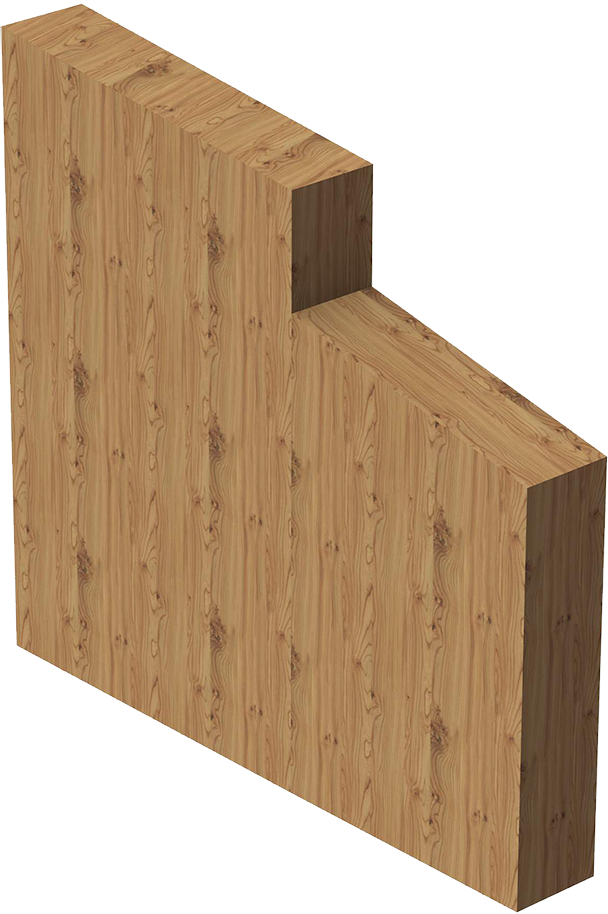

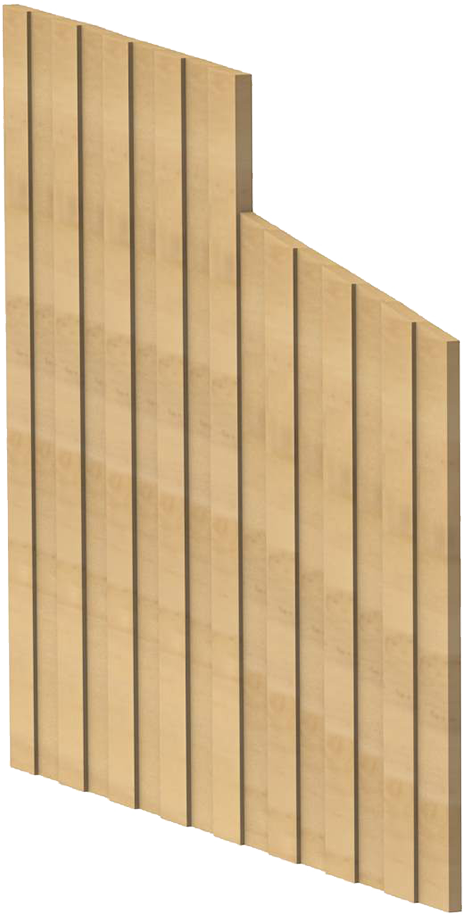

TIMBER MODULES

Modular timber construction with the natural high-tech material: wood

Wood is a composite building material reinforced with cellulose fibres with a high proportion of voids. For us this material is therefore a natural “high-tech” product. Although it is lighter than steel, it is generally more stable and, in contrast to concrete, can still absorb large tensile forces. Furthermore, it also has the very best thermal insulation properties.

If the surface is untreated or remains open-pored, wood creates healthy and comfortable room climate, as moisture is regulated in a natural way. To sum up, it is perfectly suited for our projects where we use pioneering energy concepts.

Wood is the future for buildings

Wood plays a key role in our modular considerations. We always stick to wood drying since it reduces the moisture content of wood before its use. No further chemical processes are needed after that. Moreover, wood binds enormous amounts of CO₂ and by reforesting the same amount of wood used, we improve the CO₂ balance.

Modular construction multiplies the proven strengths of timber construction. It is more precise in production, faster in construction or assembly, more efficient, and therefore more cost effective. The economies of scale outlined here can only be achieved by means of a high degree of prefabrication and the use of industrial manufacturing techniques.

In addition to the high degree of prefabrication, our timber modules are easy to dismantle and are recyclable.

1

2

3

4

5

WOOD PROFILE (Facade)

SOFT WOOD FIBER PANEL

CROSS LAMINATED TIMBER (CLT)

SOFT WOOD FIBER PANEL

INTERIOR WOOD CLADDING

Interesting facts about wood

Germany alone has a forest area of around 11.1 million hectares, which is around 30% of the total cultivated area. The wood supply in our forests is around 3.4 billion cubic metres. These forests alone extract over 600,000 tons of CO² from the atmosphere every day. This corresponds roughly to the amount produced per second by three drivers per year. To produce one tonne of wood, trees remove around 1.9 tonnes of climate-damaging CO² from the atmosphere and store 500 kg of carbon.

[The future of buildings is CO2 neutral: Thanks to reforestation

If we use wood to manufacture our modules and reforest at the same time, the carbon stored in the wood and thus the corresponding CO² equivalent is withdrawn from the atmosphere during the useful life of the wood. As a result, the use of wood counteracts the accumulation of CO² and thereby the greenhouse effect.

Good side effect: We create a healthy indoor climate and rooms where you can feel good.

Modular timber construction - advantages:

- modular timber construction leads to an almost dry production chain

- modular timber construction enables even more precise production, even faster assembly,

- neven more cost-effective construction compared to other module variants

- modular timber construction is recyclable and thus makes a contribution to climate protection

- modular timber construction leads to a pleasant, homely living environment

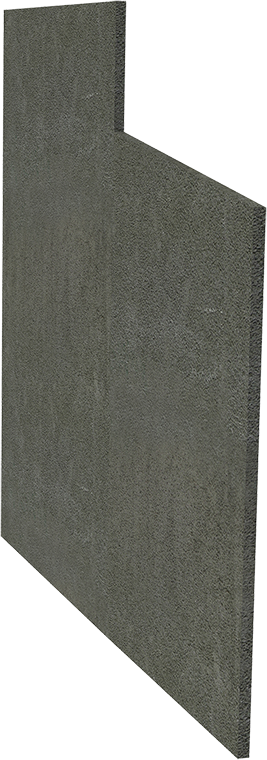

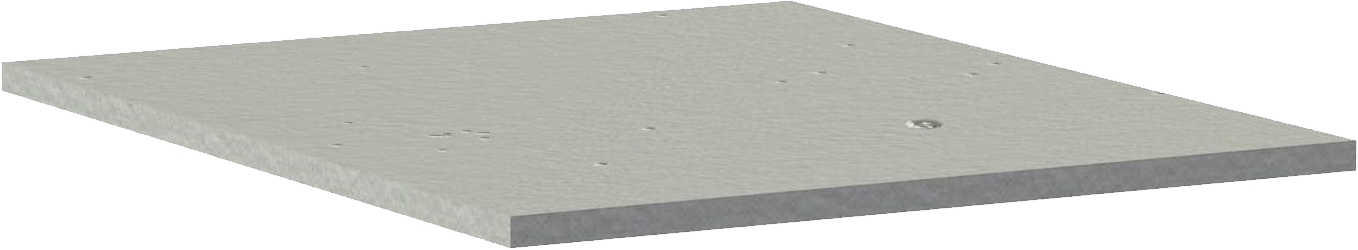

CONCRETE MODULES

Make use of exciting opportunities: Concrete modules

Our concrete modules combine all the useful properties of this building material and at the same time eliminate the disadvantages of conventional on-site construction. The modules are manufactured in the interior of the production plant, which ensures a controlled, automated, and weather-independent environment. The system is prefabricated and planned by using highly developed BIM technology (Building Information Modelling). This saves us significant time, costs, reduces construction waste and thereby ensures a considerable increase in efficiency.

1

2

3

4

5

6

7

FINAL COATING

FLUSH-MOUNTED

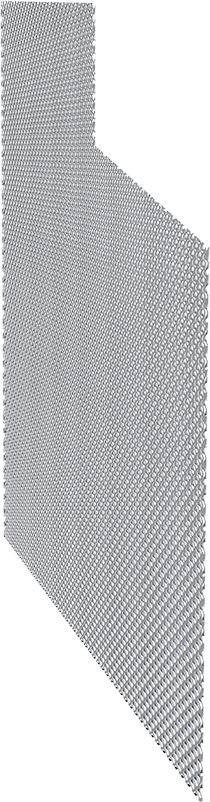

WIRE MESH

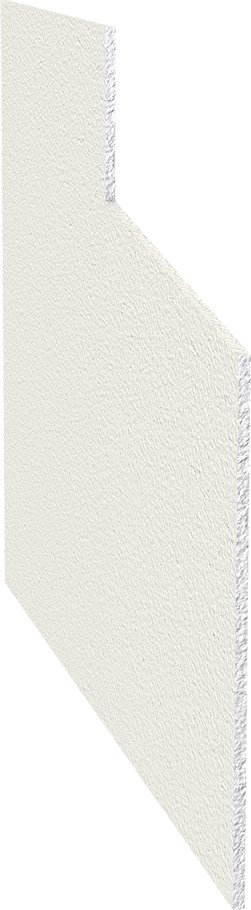

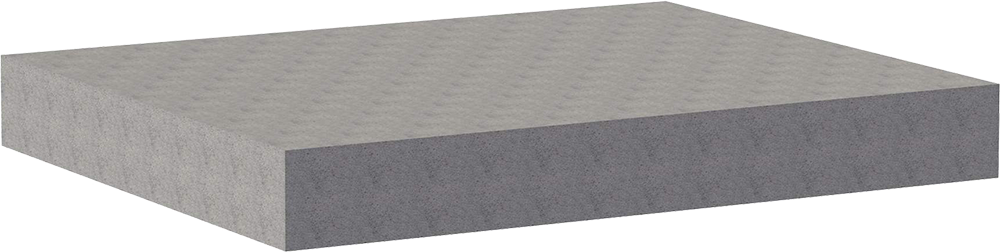

THERMAL INSULATION PANEL

ADHESIVE LAYER

EXPOSED CONCRETE

INTERIOR PLASTER

Interesting facts about concrete

Concrete is undoubtedly the most widely used material in the age of modern and postmodern architecture. This is due, among other things, to its high flexibility in terms of design forms and structural engineering capabilities. Concrete has a high compressive strength and a corresponding tensile strength to withstand natural forces. During its entire life cycle, concrete requires only minimum maintenance and is also highly resistant to biotic and abiotic decay. The most important property, however, is its fire resistance.

Prefabricated residential modules instead of conventional in-situ concrete on the building site

The conventional pouring of in-situ concrete on the construction site requires the mobilisation of building materials, supports, formwork, scaffolding and labour. This requires long construction times and therefore often results in an increased construction budget. Since the construction activity is carried out outdoors, this makes quality control more difficult, which can often result in reworking, causing project costs to skyrocket and time management to falter. That is why we use prefabricated concrete modules for our modular construction.

Concrete modules - advantages:

- Concrete modules are fire resistant

- Concrete modules are resistant to biotic and abiotic decay

- Concrete modules achieve Lean Construction Principles

- Concrete modules cause low maintenance costs despite their long life cycle

- Concrete modules ensure high construction quality

- For all the CO2 that is caused during the series prefabrication as well as on the construction site, we plant trees to ensure a CO2-neutral project!

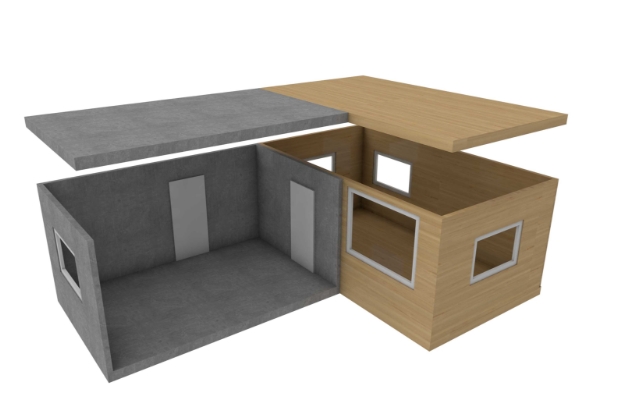

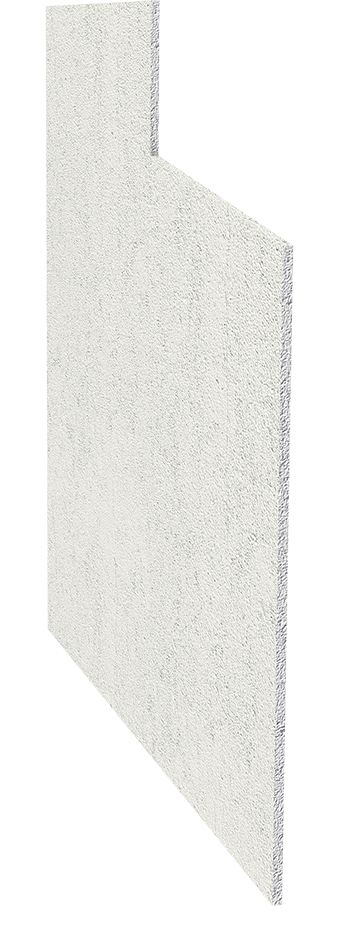

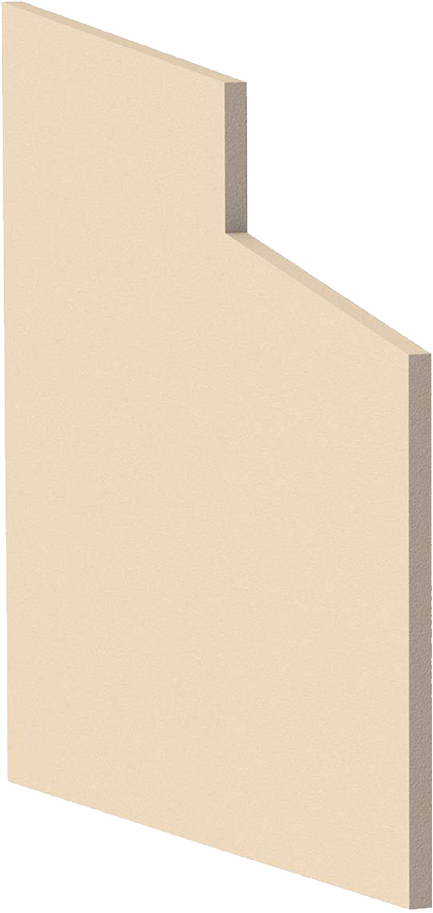

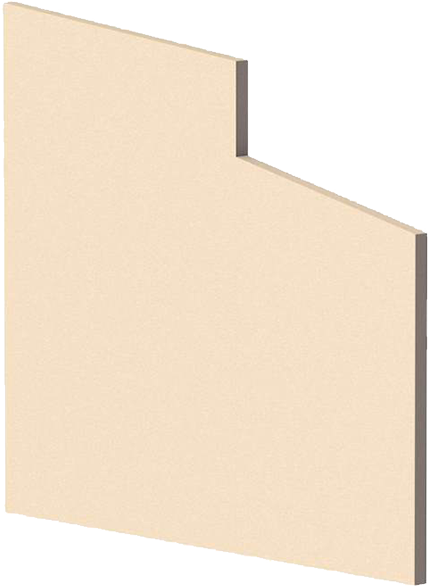

HYBRID MODULES

The combination makes the difference: hybrid modules

The hybrid modules we use are the way to pursue high performance in many respects: the floor slab forms a concrete foundation with the technical elements already integrated. All four enclosing walls are made of solid wood and provide a pleasant atmosphere and a moderate room climate, since wood absorbs any humidity when required or releases it again. The ceiling rounds things off with another concrete slab. Hybrid modules combine the sound insulation and fire protection properties of the concrete elements, as well as the pleasant atmosphere and climate regulation that wood provides. Furthermore, the contrast between both materials is used to increase the aesthetic look of buildings.

A hybrid construction exploits the advantages of timber construction and those of concrete construction to equal parts. As a result, our buildings are particularly well suited for any type of usage and offer the best characteristics for a lifetime.

1

2

3

4

5

6

7

8

9

CONCRETE CEILING

THERMAL INSULATION PANNEL

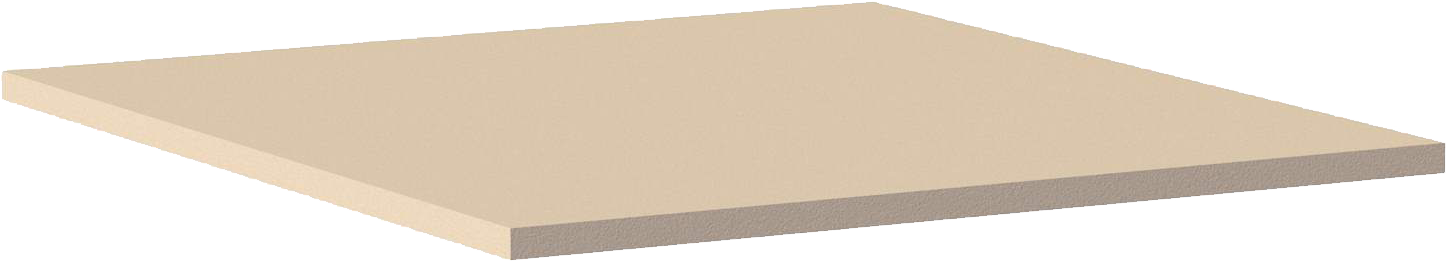

SCREED

COATING

OUTER WOOD PROFILE FORM-WORK

SOFT WOOD BARREL PLATE

CROSS LAMINATED TIMBER (CLT)

SOFT WOOD BARREL PLATE

INTERIOR PLASTER BOARD

Interesting facts about hybrid construction

The concept of hybrid construction combines the best properties of both materials for an optimised result. Functions and areas that require high strength and have to be water and moisture resistant, such as the kitchen and bathroom, are preferably cast in concrete. On the other hand, wooden modules are suitable for bedrooms and lounges due to their pleasant atmosphere features.

Hybrid modules - advantages:

- Hybrid modules combine different building materials in the same structure (concrete or wood)

- Hybrid modules combine strength, functionality and aesthetics

- Hybrid modules are flexible, optimised, logical and intelligent

- We practise reforestation for every tree felled!